Secure Accommodation Blocks

Dynasystems Universal Construction System (DUCS)

DUCS Design

The Dynasystems Universal Construction System (DUCS) is a flexible building system which consists of a pre-fabricated framework allowing for rapid on-site assembly.

As a modular system, units can be used individually or combined to create more complex structures which provide solutions for a variety of requirements.

The expeditionary nature of the system allows for the construction of a fully protected structure within hours or days as apposed to normal construction practise that can take several weeks.

In comparison to conventional systems, the DUCS is lightweight and requires few resources for transport and construction. Skilled labour is not required, and the structure is designed to be assembled with hand-tools.

Planning considerations include cost, length of deployment, threat-level, political perception, and the likelihood of reuse.

It has been designed with simplicity in mind.

DUCS Protective Housing

The flexible system can be used on expeditionary military operations that need either permanent or relocatable structures.

The system was designed with protection in mind and a wide variety of materials can be used to protect against blast and ballistic threats.

It uses advanced material science and energy absorbing technology for protection, providing redeployable modules.

As a modular system, it provides great flexibility in the planning stage, and can be used to provide a range of facilities, from accommodation blocks to extensive medical units.

DUCS Low-Cost Housing

The system offers the ability to construct a variety of buildings to a set design in remote areas “straight from the crate” and with the maximal use of local available materials and resources. The flexibility of the entire system gives the end user a number of options that previously have not been available.

The structures can also be used in response to a natural disaster where housing is needed at short notice.

The materials used can be adapted to local requirements in relation to fire hazards and structural integrity.

DUCS Protection

The level of protection in DUCS is scalable, in accordance to operational requirements.

DUCS structure has achieved the highest level of ballistic and fragment protection, protecting its occupants from direct fire threats that exceed 0.5 cal bullet and fragments in excess of 155 mm rocket warheads.

The system also provides the highest level of protection against VBIED and other explosive events. In full-scale explosive tests, it achieved performance that exceeds pressures of 1,000 psi and impulses of 1,200 psi.msec emanating from charge ranging up to 2,000 kg of explosive.

All test and trial have been undertaken and documented by a number of international authorities including US Army Corps of Engineers, US TSWG, US Air Force Research Laboratories, NL TNO, UK MoD, and UK Royal Engineers.

See Also:

Dynacell

Lightweight, Modular and Transportable

Blast and Ballistic Structures

Expeditionary Design

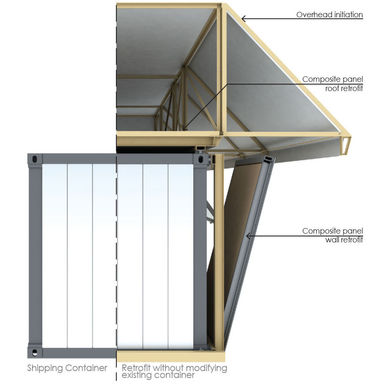

Dynacell is a modular structure which is made up of blast and ballistic protection materials. The Dynacell is designed using lightweight materials for the ease of transport.

It can be supplied as an assembled base unit or as a “flat-packed” system that can be erected by local tradesmen without any requirements for heavy construction equipment. This is achieved by a specially designed structural folding frame.

Once the shelter frame structure has been created, the protective envelope is then installed.

Sustainable Design and Materials

The envelope is made out of lightweight unique composite panels that provide excellent thermal, acoustic and fire resistant properties by the use of proprietary developed material that form part of the composite panel. Dynasystems is dedicated to using environmentally friendly processes and materials that have a high degree of reusability.

Damaged panels can be returned for recycling and reuse to ensure limited impact on the environment. Many containerised accommodation units utilise polyurethane foam as the insulation layer which gives off toxic gases during combustion. The Dynacell uses materials which have a high degree of fire resistance and are not life threatening. Efficient insulation is created without compromising safety or the environment

Proprietary Design

The Dynacell’s unique performance is attributed to innovative blast energy absorption technologies and specially developed materials. All Dynacell components, materials and their applications are proprietary and protected by numerous registered international patents.

Maximal Blast and Ballistic Protection

The Dynacell structure is designed to provide the maximum available protection against Blast and Ballistic threats. The ballistic protection is achieved by the use of ballistic layers that are embedded inside the composite panel. The exact level of protection is determined by the client and will be incorporated in the panel design.

The blast protection of the shelter is achieved by the use of a unique and proprietary energy absorbing sub-frame system. This system absorbs a significant part of the energy transferred to the structure by the blast and absorbs it by deflection and movement, thus significantly reducing the forces transferred to the shelter structural frame. This technology has been proven over the last five years in dozens of UK/US recognised full scale tests and is widely implemented worldwide.

Enhancement of the Protective Measures

The Dynacell protection capabilities are designed to be upgraded at any stage of its life to meet ever changing and emerging threats. This can be achieved by various modular components designed to be integrated on the base structure. These include an “overhead” initiation module that will enable the shelter to resist direct hits from rocket and artillery shells.

An optional side panel initiation screen that will provide protection against Anti-Tank shaped charges and other shoulder launched weapons can be installed.

Specification

The Dynacell product has undergone full scale explosive and ballistic testing in order to certify its performance against commonly used weapons as defined by STANAG 2280 – “Design Threat Levels and Handover Procedures for Temporary Protective Structures.”

Tests have been performed by certified third-party laboratories and also by official UK Government entities.

The Dynacell technology is constantly being improved to meet new and emerging threats.

Testing and Certification

Dynacell has undergone continuous testing and development in live fire exercises to ensure its reliability. These tests have been conducted with and in accordance to those standards approved by NATO, US TSWG and UK MOD, amongst others. Pressure gauges are used to simulate the damage caused to the human body. The Dynacell survived the most severe tests with little or no over pressure and absolutely no spalling. The effectiveness of the design has been proven to minimise injury and loss of life. Full performance certification of the design is provided by a third party specialist security company.

See Also: